If you’re standing all day, struggle with plantar fasciitis, or wish you had more support for heels or hiking, great insoles can help.

But, how do you know if the insoles are any good?

Look at how they’re built.

Orange Insoles have a unique, four-layer construction designed to offer great support - and last a long time. That’s why we think they’re the best insoles out there. ;-)

Insole Layer 1: Polyurethane Base

The first layer of the insole is its casing.

If you flip the insole over, you’ll see the black plastic piece. This is the casing. Its job is to hold the insole together and gives it its shape. Its molding is what creates the deep heel cup that locks the heel into place.

This deep heel cup is a unique feature of Orange Insoles that actually pulls the fatty tissue around your heel underneath it. This provides natural shock absorption.

Most other insoles are shallow, which doesn’t give this fatty tissue good shock absorption.

The casing itself contains EVA compressed foam compressed into different densities at different parts of the insole. To create the deep heel cup we’re so proud of, we had to open a custom mold and generate a unique design.

Insole Layer 2: Plastic Molding

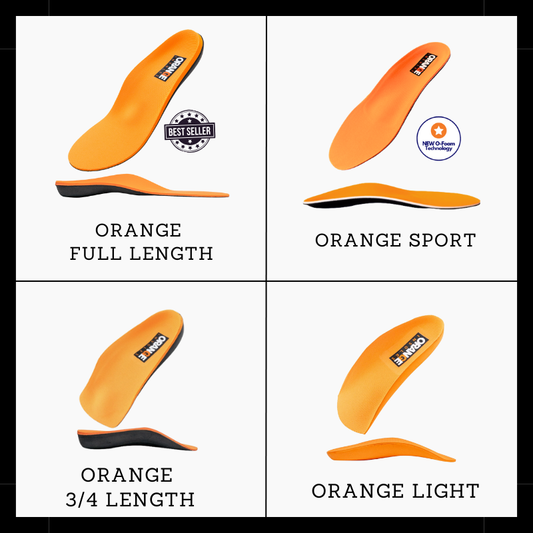

The next layer up is the thermo-plastic insert that gives the insole its contour and is offered in the FULL LENGTH (Best seller $38) and the 3/4 Insert ($30).

This insert helps with alignment and provides comfort by distributing your body’s weight more evenly across the heel, forefoot, and arch.

It does this by providing lift & separation that spreads out the weight effectively.

This layer also creates the medial arch and metatarsal pad that many customers rely on for comfort, fit, and support.

This layer was designed based on observations made in a retail environment. We found that customers frequently added metatarsal pads to other insoles in order to replicate the benefits we now provide “out of the box.”

The plastic molded piece also keeps the structure of the insole intact to last the length of your shoe life.

So, we watched, learned, and designed this layer to meet customer needs.

Insole Layer 3: High Impact EVA Foam

The EVA foam layer helps soften the firm contour of the shoe insole. We offer this on all 3 types of Orange Insole designs.

Without it, the insole would offer great support...but feel hard. You’d really feel it on hard surfaces because there’d be no shock absorption.

This layer is what provides the shock absorption that prevents your body from feeling every impact from your day-to-day activities - be it running, golfing, hiking, hanging at a tailgate, or just standing around looking fancy in your heels.

Insole Layer 4: Micro-Fiber Fabric

The final layer of the insole is a fabric cover designed to spread the moisture from your foot out - so it evaporates faster. This is offered on all our products.

Yes, we know that sounds gross.

But, the reality is that it’s a protectant for your insole that allows them to last longer, and prevent moisture from gathering in your shoes.

Because, when moisture gathers in your shoes, bad things happen - things like blisters, uncomfortable temperature, and odor.

The fabric works a bit like the way a squeegee on a tennis court works - moisture gathers, fabric spreads, moisture evaporates.

Boom.

The Best Insole (So Far)

The construction of Orange Insoles was entirely motivated by customer feedback and observations of where other insoles fell short.

That’s not to say there aren’t other great products out there.

Many customers have great results with them.

We just know our insoles are better. Don’t believe us? Why not order a pair today and try them out yourself. We know you’ll be back after you do!